August 31, 2009

New tool to aid in wrapping baren

David Bull alerted me of a new tool available from Matsumura-san. It is an ingenious device to aid in holding down the baren pad while wrapping a new bamboo skin. You'll find these in the Baren Mall under the 'Printing Accessories' section ...

Here are some videos of the tool in action courtesy of the Woodlike Matsumura website.

Part 1.

Part 2.

Part 3.

Posted by Julio at 12:28 PM | Comments (0)

February 3, 2009

Japanese woodblock technique

Here is a short video demonstrating the Japanese woodblock tecnique. The first 30 seconds or so are slow but then we see the traditional bench setup, tools and techniques.

Do not know who the craftsman is in the video but by the looks of the room I am guessing it was filmed at one of the Hanga studios in Japan that create Ukiyo-e reproductions and are open to the public.

Note the use of a small water bottle to keep the sharpening stone wet and the use of the left hand to guide the aisuki clearing knive. Also note that the carving and printing benches are set at opposite angles to improve technique and reduce effort.

Posted by Julio at 3:00 AM | Comments (0)

January 25, 2009

Homemade press

This short video shows a homemade press that can be used for letterpress and possibly other forms of relief printmaking. Pretty ingenious and inexpensive design.

Posted by Julio at 5:57 AM | Comments (1)

Letterpress Documentary

Here is a very nice documentary about letterpress and the tools and equipment required.

Posted by Julio at 5:38 AM | Comments (0)

September 11, 2005

Two Hand Print

To keep track of the colors I used, I listed them on the back of the block.

I've also posted my "kento" method, it worked for me.

Also, in case anyone is interested, I started with 25 prints and finished with 20 good ones, so only 5 wasted.

Posted by Daniel Dew at 6:12 PM | Comments (1)

June 29, 2005

CNC-machine pen and ink drawing

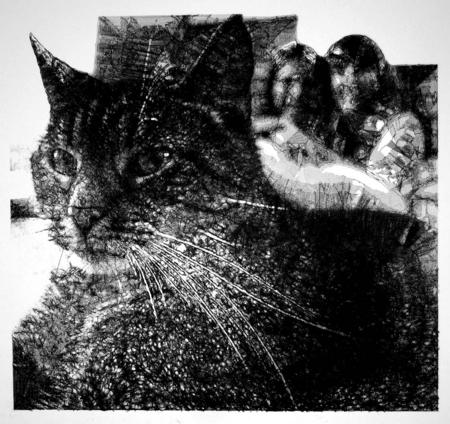

"Girls and Cat" click image for enlargement

This is a pen and ink drawing (black rolling writer on BFK) made by CNC Machine. The pen paths followed the contours of the gray areas of the digital image used as a 'map'. The first contours drawn were those which were the darkest tones in the image. The pen more or less follows the outer contours, spiraling inward about 30 lines per inch. Then the contours of the two darkest tones toghther, then the three darkest tones, and so on until the contours of all non-white tones were drawn last.

Here's a detail of the cat's face:

detail -- click for enlargement)

The lines do an interesting job of approximating the gray-tones of the original image and leave those complex criss-crossed curvy contours on the paper which I think are very beautiful!

The drawing took about 8 hours to complete at about three inches per second -- over a mile of line on this 14 x 14 inch drawing!

Posted by at 11:18 AM | Comments (4)

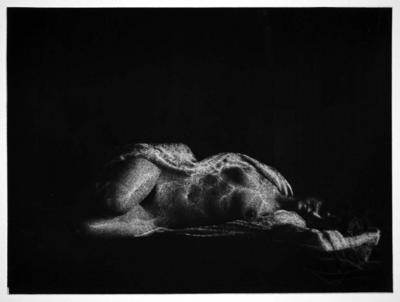

CNC-machined Sarah mezzotint

click image to pop-up enlargement

The copper plate for this mezzotint was entirely produced by CNC machine holding two conventional EC Lyons tools -- a diamond-tipped dry-point graver which was used to scribe a series of parallel lines at 50 lines per inch over the entire plate, then another set of lines at a 15 degree angle to the first set, and so on through 180 degrees.

Then a small ball-end burnisher was used to burnish out the highlights in about 13 steps...

First the machine followed the contour of all non-black areas, then all but the two darkest areas, then all but the three darkest areas, and so on until the final pass burnished only the lightest areas.

The plate was then inked, wiped, and printed as usual with intaglios.

Posted by at 10:40 AM | Comments (0)

CNC machined drypoint and mezzotint

This is "Mia", printed on tan Rives BFK paper from an 18x12 inch copper plate.

The copper was drypointed and burnished entirely by my CNC machine, following paths I generated from my digital image and using EC Lyons conventional tools fixed in a special jig I made for the machine.

The plate was held flat during machining by a simple vacuum plenum powered by a shop-vac!

email Mike Lyon

Posted by at 6:49 AM | Comments (3)